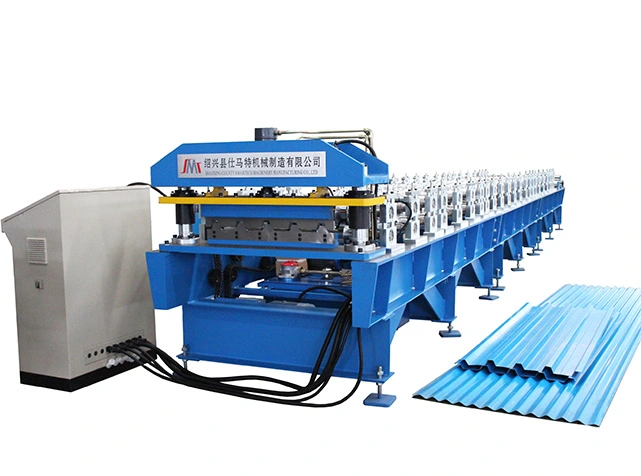

Metal roof/wall panel roll forming machine is a specialized equipment used in the construction industry to produce metal panels for roofing and wall applications. Our economic roof or wall roll former has a solid frame with guide column shaft bearings. This enables you to forming raw material from thickness 0.4mm to 0.7mm. Production speed varies from 20 meters per minute to 50 meters. Every line has PLC control which you can set the length and blocks you want to produce and the roll former will start producing as the set parameter. Thus it is a quite efficient metal panel making line. Smartech Machinery Company offers high efficient sheet metal roofing machine for sale to satisfy your need.

Our smartech msachinery roof or wall panel roll forming machine consists of decoiler, feeding device, roll forming stations, hydraulic or motor cutting device and an electric controlling system. You can also require to add pre-cutter device, filming device, safety guard device and automatic stackers for options. We use guide column shaft bearing for metal roofing roll formers, it is easily for adjusting the gap between up and down rollers while the running material thickness is changed. By a specific set of roller stations, the metal profile can be formed step by step and finally forming to the shape as the confirmed profile drawing. For length of sheets, you can put in the touch screen so the sheets will be cut at the set length by control of PLC and Encoder. It is a full automatic and continuous forming machine for metal sheets.

Roof or wall panel roll forming machines come with a variety of features just like our other products such as upender machine designed to enhance their functionality, efficiency, and ease of use. Here are some of the key features:

1. High Precision Rollers: Typically made from high-grade steel or chrome-plated to ensure durability and precision;

2. Advanced Control Systems: With PLC control and touchscreen interfaces for easy operation and monitoring. And you can also choose to get a remote control for easier operation while running the machine.

High Efficiency: Continuous production and high-speed operation significantly boost productivity.

Precision: Ensures accurate dimensions and consistent quality, reducing material waste.

Cost-Effective: Lowers labor costs and minimizes material waste, making the process economical.

Versatility: Customizable designs and material flexibility cater to various architectural needs.

Durability: Produces strong, weather-resistant panels ideal for long-lasting applications.

User-Friendly: Advanced control systems and low maintenance requirements enhance ease of operation.

No | Item | Parameter | Remark | |

1 | Suitable Material | Type | PPGI | |

Width (mm) | 1250 | customize | ||

Thickness (mm) | 0.4-0.7 | |||

Yield Strength (Mpa) | 230-300 | customize | ||

2 | Forming Speed (m/min) | 20/30/40/50 | customize | |

3 | Roller Material | No.45 steel with Chromeplate | Up to buyer | |

4 | Roller Shaft Diameter | 80 | customize | |

5 | Cutting Model | Hydraulic/Electric Cutting | ||

6 | Power source | Type | 380V/3PH/50HZ | Up to buyer |

Total Power | According to actual design | |||